| Author |

Topic Topic  |

|

|

Russ Jackson

United Kingdom

190 Posts |

Posted - 10/06/2025 : 08:30:45 Posted - 10/06/2025 : 08:30:45

|

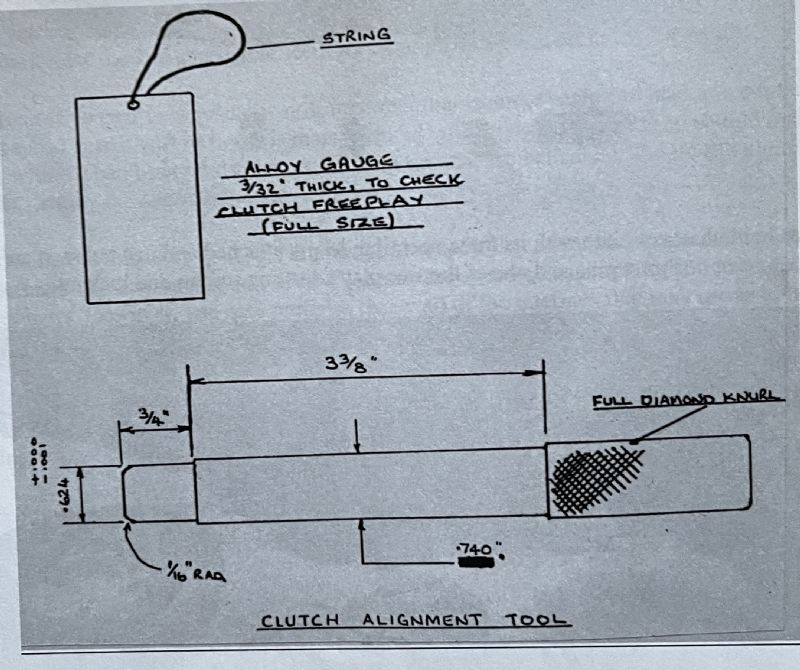

firstly I'd like to buy this book "A practical guide to the restoration of the "J" type (1932-34)" by G. Howell see attached image failing that there is a drawing of a clutch alignment tool on page 40 in the section "Engine and gearbox" any chance if someone has this book that they could possible take a picture of the said tool and either send it to me or post it up here please......

(I may not be a clever man but I know someone who is) |

Edited by - Russ Jackson on 10/06/2025 08:42:11 |

|

|

Ian Bowers

United Kingdom

969 Posts |

Posted - 10/06/2025 : 08:45:13 Posted - 10/06/2025 : 08:45:13

|

Not p40 !

Indeed I can't find any drawing of such a tool in my copy. My cover colour is orange (2009 edition) so there may be more than one version.

Any other suggestion?

Ian Bowers

OD 6791

J3 3772 |

Edited by - Ian Bowers on 10/06/2025 08:47:07 |

|

|

|

coracle

United Kingdom

2305 Posts |

Posted - 10/06/2025 : 09:19:08 Posted - 10/06/2025 : 09:19:08

|

I use a spare first motion (input) shaft to do the job.

All you need is a stepped shaft that is a good fit through the clutch driven plate splines and slots into the spigot bearing to hold the driven plate centrally as the clutch cover is tightened up against the springs. |

|

|

|

Simon Johnston

United Kingdom

6629 Posts |

Posted - 10/06/2025 : 09:35:00 Posted - 10/06/2025 : 09:35:00

|

Itís page 82.

Simon J

J3437

Edit: to correct page number! |

Edited by - Simon Johnston on 10/06/2025 09:36:43 |

|

|

|

Russ Jackson

United Kingdom

190 Posts |

Posted - 10/06/2025 : 10:41:30 Posted - 10/06/2025 : 10:41:30

|

thanks Chaps....blast only 40 pages out LOL......so you can't actually use the tool to align the splines on the pressure plate.....not that it matters too much it'll just make sliding the first motion splined shaft into the clutch and spigot bearing that little bit more difficult.....not a whole hill of beans to be fair

(I may not be a clever man but I know someone who is) |

Edited by - Russ Jackson on 10/06/2025 10:43:00 |

|

|

|

Russ Jackson

United Kingdom

190 Posts |

Posted - 10/06/2025 : 10:44:34 Posted - 10/06/2025 : 10:44:34

|

anyone got a copy of that book they want to sell or know who has one for sale S & V I don't think have these in stock anymore nor do the Octagon MCC

(I may not be a clever man but I know someone who is) |

|

|

|

coracle

United Kingdom

2305 Posts |

Posted - 10/06/2025 : 11:07:57 Posted - 10/06/2025 : 11:07:57

|

[quote]Originally posted by Russ Jackson

thanks Chaps....blast only 40 pages out LOL......so you can't actually use the tool to align the splines on the pressure plate...

... it'll just make sliding the first motion splined shaft into the clutch and spigot bearing that little bit more difficult...

(I may not be a clever man but I know someone who is)

[/quote

That is exactly what it does, keeps the driven plate centrally on assembly.

If the driven plate is not well centralised it can make getting the first motion shaft through and to the spigot bearing very difficult, if not impossible.

P.S. one might categorise the "full diamond knurl" together with "bells and whistles." |

Edited by - coracle on 10/06/2025 11:18:31 |

|

|

|

i.thomson

United Kingdom

423 Posts |

Posted - 10/06/2025 : 13:26:59 Posted - 10/06/2025 : 13:26:59

|

Firstly, there are at least a couple of versions og Graham's book, which may well have different covers. I have copies of the riginal version(s) which comes in three parts. A later version puts all three in one copy. BTW what happened to Graham? I have not heard from him for a long time. He helped me a lot when I first got my J2. Secondly, there is no need to have a bespoke clutch alignment tool (though I'm sure it helps). I have often made up a rough and ready version from a short length of 15mm copper pipe wrwpped in duct tape to fit the two diameters (spigot bearing and clutch splines). I have used this method on a variety of engines (including my J2) to good effect.

Ian |

|

|

|

Ian Grace

United Kingdom

724 Posts |

Posted - 14/06/2025 : 11:35:57 Posted - 14/06/2025 : 11:35:57

|

This might be a good point to mention that, when removing the gearbox, don't let it hang on the input shaft, as this can seize the input shaft in the tail end bearing in the flywheel, and then you'll have difficulty withdrawing the box. I had this problem way back in 1977 with my first Minor and it took a couple of tire levers to prise the box off! The trick is to remove the top bell housing bolt last and before that, support the weight of the box.

Also, do remember to remove the propshaft first! Someone actually asked me that when I had trouble getting my gearbox off and I asked for advice!

And no, the aligning tool only centres the driven plate and doesn't align the splines. But it's no biggie to fiddle it in.

|

|

|

|

Nick Feakes

USA

3619 Posts |

Posted - 16/06/2025 : 07:55:28 Posted - 16/06/2025 : 07:55:28

|

A trick I learned a long time ago was to engage top before trying to fit the gearbox. It is then easy to rotate the input shaft using the propshaft drive flange.

Nick |

|

|

|

Russ Jackson

United Kingdom

190 Posts |

Posted - 24/06/2025 : 10:26:57 Posted - 24/06/2025 : 10:26:57

|

thanks Chaps new Sealed Clutch Spigot Bearing fitted with a little Loctite anti torque lock, New Clutch Springs, didn't need Friction Plates as still 1/8" thick just deglazed them and the plain pressure plate new Clutch fingers new washers and felt washers with new Split pins for the pivot pin also new retaining Spring clip stops....the width of the thrust bearing engagement pads are almost 2x the width? new Thrust pins then installed using S&V aligning tool and bolted up the fly wheel cover plate nice and tight with a dab of Loctite as well as the spring washers so that was the relatively easy bit then onto the gearbox with a new Thrust Bearing and cover which I packed with grease before fitting into the thrust cover greased the clutch shaft bronze bushes popped on the thrust bearing with a dab of grease on the fork ends a smear of oil on the thrust bearing spigot shaft and put it altogether.....then onto the heavy lifting and threading of the needle of getting the gearbox and Bellhousing mated together....I used a block of wood and my Trolley jack....with a lot of heaving and jiggling I managed to get the first motion shaft aligned with the pressure plate and finally with the spigot bearing.....sweating cobbs I was....LOL all bolted up including the fume shield mines in 2 halves.....I have a new bottom end fume H pattern rubber seal I'll work that in place after I've decided the clutch actually does it's job I also adapted a P type clutch pedal stop but I need to fine tune it task for today to set the clutch finger clearance and then the thrust pin clearance a job I suspect that'll be harder than it sounds....then later this week finish off the final assembly propshaft tunnel floors seats.....then off a drive to see if the horrible metallic screech has stopped fingers crossed......there are a few more jobs to do just to tidy up the first will be to stop the damned Sump leak.....I wont be messing about it'll be a new Sump new Studs new nuts and washers and a liberal smear of Permatex Ultra Grey and finished off with a new Oil Filter and a Gallon of fresh Castrol XL30....but that's for later.......cheers chaps

(I may not be a clever man but I know someone who is) |

|

|

| |

Topic Topic  |

|